Brominated flame retardants are crucial for enhancing safety by reducing the risks associated with fires. These chemicals play a significant role in both personal safety and property protection by slowing the spread of flames, which provides valuable time for individuals to respond to a fire event. Whether in homes, vehicles, or public buildings, these retardants contribute to minimizing potential damage and ensuring safety compliance.

Understanding how brominated flame retardants function is important for appreciating their impact on everyday life. They interfere with the combustion process, which helps prevent fires from escalating rapidly. This enables easier evacuation or fire control efforts, significantly reducing potential hazards.

What is Brominated Flame Retardant?

Polymer science has advanced considerably during the past few decades, which has led to the introduction of numerous polymers with various applications and characteristics. Resultantly, we are surrounded by polymers in various items of everyday use, including furniture, clothing, electronics, computers, and vehicles.

The majority of the polymers are flammable as they are petroleum-based. Therefore to make these products safe and to meet fire safety standards, flame retardants are added to natural and synthetic polymeric materials like wood, plastic, textiles, and paper to enhance their flame retardant capability.

Flame retardant chemicals are generally divided into four categories; inorganic flame retardants like magnesium hydroxide, halogenated flame retardants including the ones based on bromine or chlorine, organophosphorus flame retardants, and organic nitrogen-based flame retardants.

Brominated flame retardant or Flame retardant bromine is a mixture of synthetic chemicals added to various products to reduce their flammability. The BFRs are mostly used in textiles, plastics, and electronic equipment. BFRs fall in the halogenated flame retardant category and account for 25% of the global production of flame retardant chemicals.

While flame retardants have four main categories, brominated flame retardants are further classified into five categories which are sold under different brand names as technical mixtures.

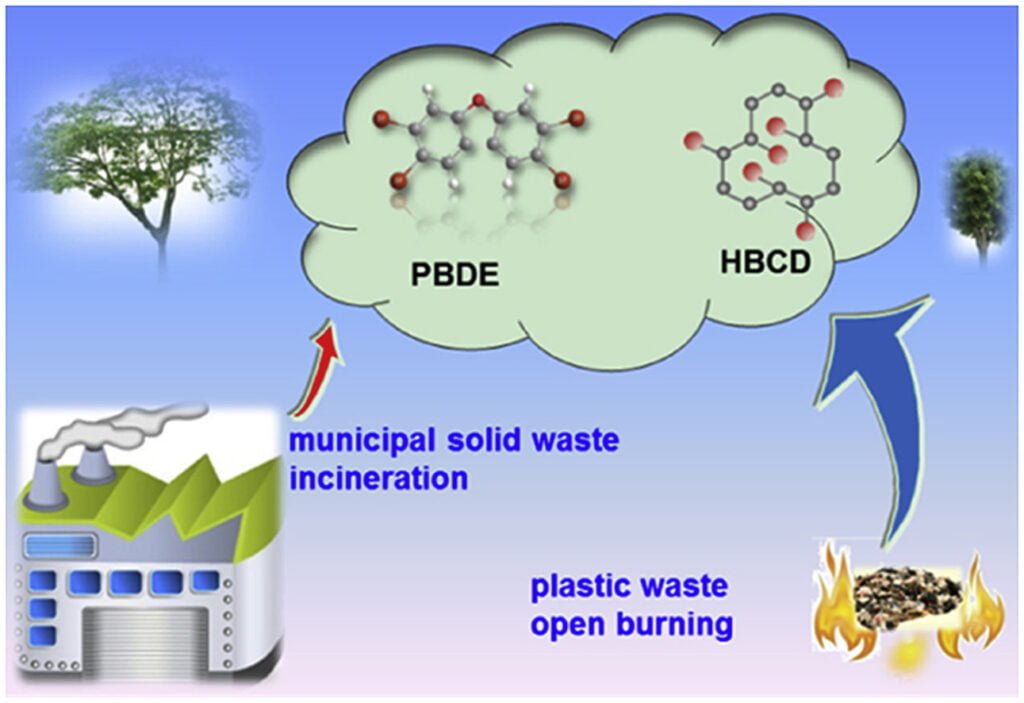

- PBDEs: Polybrominated diphenyl ethers- these are used in plastics, textiles, circuitry, and electronic castings

- TBBPA: Tetrabromobisphenol A- used in thermoplastics and printed circuit boards

- PBBs: Polybrominated biphenyls- used in textiles, consumer appliances, and plastic foams

- HBCD: Hexabromocyclododecanes- used for thermal insulation in the building industry

- Other BFRs

Of these, the flame retardant PBDE, TBBPA, and PBB are classified as Aromatic BFRs, HBCD are classified as cycloaliphatic, and the other BFRs used in small quantities are classified as Aliphatic.

How Does Brominated Flame Retardant Work?

The combustion process comprises four steps, including preheating, decomposition, ignition, and propagation. Flame retardants serve their purpose through chemical or physical modes of action. The flame retardant can act at any of the four steps of the combustion process, depending on the mode of action. Here is a brief account of both.

Physical Action

On the other hand, the physical action is divided into three modes. In the first mode, a cooling action takes place. The additives cool the substrate to make it reach a temperature level below the required level for the combustion to continue, thereby triggering the endothermic process.

In the second mode, a solid or gaseous protective layer is formed on the combustible layer to protect it from the gaseous phase. This inhibits oxygen that is required for combustion and blocks heat transfer.

In the third mode, fillers are added to convert inert gases to disintegration. This dilutes the fuel in the gaseous and solid phases and inhibits the gas mixture’s ignition limit from exceeding.

Chemical Action

A chemical action has two modes. In one mode, the flame retardant forms a layer of carbon on the surface of the polymer by dehydrating the flame retardant. This causes the formation of a carbonaceous layer via cross-linking, which provides insulation and prevents the material from decomposing further.

In the second mode, the flame retardant reacts during the gas phase and interrupts this stage during combustion. This stops the exothermic process, causing the system to cool down and suppress the flammable gases.

Are Brominated Fire Retardants Effective?

Brominated fire retardants play a role during the gas phase when things are burning. Bromine is key here. It’s known to bind with high-energy radicals, forming compounds that are less reactive. This stops the dangerous reactions that keep fire burning.

Bromine mainly reacts with hydrocarbon compounds, and this forms a substance known as hydrogen bromide. Hydrogen Bromide is important because it breaks up the high-energy radicals like OH and H. By doing this, it reduces the fire’s energy and slows the burning.

The effectiveness of brominated fire retardants really depends on how much bromine they have. They can contain anywhere from 50% to 85% bromine by weight. The way these compounds work is similar across the board, though some may perform better than others. The impact they have on the properties of the materials they are in also varies.

- Bromine’s Role: Captures radicals, hinders flames

- Hydrogen Bromide Formation: Reduces fire energy

| Feature | Details |

|---|---|

| Effectiveness Range | 50-85% bromine content |

| Chemical Reaction Sites | Gas phase interactions |

Brominated fire retardants are a diverse group but work under a common mechanism. The differences lie in how well each compound performs and how they might alter the physical properties of the product they are used in.

The Use of Brominated Flame Retardant

Brominated flame retardant is commonly used to diminish the flammability of various items used commonly in households or offices, like fabrics for clothing, carpets, upholstery, furniture, mattresses, and plastic like computer cases, etc. Bromine-based flame retardant can also be used for making insulation products and the inner fittings of vehicles.

The main criteria for using brominated flame retardant are stability during the product’s lifecycle and its compatibility with the polymeric material. It is why almost eighty different variants of brominated flame retardant are available commercially. The most commonly used are PBDEs and polybrominated diphenyl ethers. With the growing usage of polymeric materials globally, the market demand for brominated flame retardant also continues to grow at a substantial pace.

Flame retardant PBDE

PBDE, short for Polybrominated diphenyl ethers, is one of the most commonly used classes of brominated flame retardant. They are produced by combining bromine with diphenyl ether in the presence of a Friedel Crafts catalyst and applied as an additive flame retardant in a variety of products. They slow the ignition and prevent the spread of fire.

PBDEs are produced in various commercial mixtures having variable amounts of fire retardant. They were previously used to improve the fire retardant capability of various products and consumer goods like textiles, clothing, coating, plastic case of electronic equipment like TV or computer, construction material, and polyurethane foam for furniture padding.

However, concerns about the toxicity for users and the environment have led to bans or restrictions on the use of PBDEs in several regions through regulatory and non-regulatory initiatives driven by concern over their impact.

As a result, most products once treated with Polybrominated diphenyl ethers are now treated for fire retardancy with other alternatives having the same kind of chemistry, which have also been used for their fire resistant applications for apparel for a long time.

One such example is THPC, short for tetrahydroxymethyl phosphorous chloride. Also known as THPS, it is mostly used to make flame retardant fabric for protective clothing that is to be worn in various industries, including oil and gas, commercial and industrial water treatment, and the textile and tanning industry. It enhances the fabric’s tear strength and protects it from bacteria and fungi, making it suitable to wear in work situations, including water.